Understanding the Science Behind Cheese Production: From Milk Choice to End Product

The detailed process of cheese manufacturing begins with the cautious choice of milk, a selection that profoundly influences the last item's taste and appearance. Understanding the pivotal role of germs in fermentation discloses just how these microbes change lactose into lactic acid, a vital component in establishing the cheese's character. cheese makers melbourne.

Milk Selection Refine

The choice of milk is a vital action in the cheese manufacturing procedure, as it straight affects the flavor, appearance, and top quality of the end product. Various factors need to be considered during this option, consisting of the source of the milk, the breed of the pets, and their diet. Cow's milk, goat's milk, and sheep's milk each possess distinctive residential properties that add to the distinct attributes of various cheese ranges.

Additionally, the dietary material of the milk, affected by the animal's diet, can change the cheese's last attributes. Top notch milk, sourced from healthy and balanced pets, ensures a remarkable cheese product, highlighting the value of rigorous top quality control measures in the milk selection procedure. Thus, careful factor to consider in milk choice is essential for effective cheese production.

Duty of Germs in Fermentation

Adhering to the careful option of milk, the fermentation process plays a critical function in cheese manufacturing, where germs are introduced to change the milk into cheese. The key function of these bacteria is to transform lactose, the sugar present in milk, right into lactic acid. This acidification not only modifies the pH of the milk however additionally plays a critical function in flavor advancement, appearance, and preservation of the last product.

Lactic acid microorganisms (LAB), such as Lactococcus and Streptococcus types, are generally used in cheese manufacturing due to their capacity to thrive in milk and their payment to the fermentation procedure. The metabolic activities of these bacteria cause the production of different metabolites, consisting of taste compounds and antimicrobial compounds, which prevent wasting organisms and pathogenic bacteria, consequently boosting cheese safety.

Moreover, the fermentation procedure influences the total characteristics of the cheese, including its scent, preference, and appearance. Various stress of microorganisms can impart unique tastes and add to the unique profiles of various cheese kinds. Hence, the selection of bacterial cultures is a crucial step in achieving the wanted cheese quality and consistency.

Coagulation and Curd Development

In celebrity manufacturing procedure, coagulation notes an important my link change from fluid milk to solid curds. This change is mainly induced by the addition of rennet, an enzyme that acts on casein, the main healthy protein in milk. When rennet is presented, it promotes the gathering of casein molecules, leading to the formation of a gel-like structure. This procedure is usually enhanced by the acidic atmosphere produced by lactic acid microorganisms, which even more aids in coagulation by decreasing the pH of the milk.

The resulting curds are created as the liquid whey begins to divide. Elements such as temperature, the amount of rennet used, and the moment permitted coagulation are necessary in figuring out the texture and top quality of the curds. Higher temperature levels and longer coagulation times generally generate firmer curds, suitable for more challenging cheeses.

Once curds are developed, they are reduced into smaller sized items, permitting whey to get away more effectively. This action is important, as it affects the dampness content and total qualities of the last cheese item. Proper administration of coagulation and curd development is vital for achieving details cheese designs and desired flavor accounts.

Aging and Taste Development

After the curd has been formed and whey has actually been drained, the following stage find out this here in cheese production is maturing, additionally known as growth. This important procedure significantly influences the cheese's final flavor, texture, and scent. Throughout aging, numerous biochemical and microbiological changes happen, affecting the general sensory account.

The aging setting, including temperature and humidity, plays an essential duty in taste growth. Enzymes and bacteria present in celebrity promote the breakdown of proteins and fats into smaller sized particles, leading to the development of amino acids, fats, and unstable substances. These improvements add to the intricacy of taste and scent, with unique accounts arising based upon the certain cheese range.

Furthermore, the duration of aging is critical; much shorter aging durations typically generate milder tastes, while longer growth lead to more robust and nuanced profiles. Elements such as the milk source, cheese Read More Here kind, and certain aging methods even more enhance the variety of flavors produced. Ultimately, aging is a fragile equilibrium of time, environmental conditions, and microbial activity, finishing in the one-of-a-kind features that specify each cheese variety.

Quality Control in Cheese Manufacturing

Ensuring high standards throughout celebrity production procedure is crucial for providing a top quality product that fulfills customer expectations - cheese shop melbourne. Quality control (QC) encompasses numerous stages, beginning with raw milk selection to the final aging procedure. Each stage calls for precise focus to detail to avoid contamination and make sure uniformity

During milk choice, producers need to assess aspects such as fat content, pH levels, and microbial quality. Normal testing for somatic cell matters and microbial loads is critical to make certain the milk's suitability for cheese making. In the manufacturing stage, QC steps consist of monitoring the temperature, acidity, and rennet activity, which dramatically affect texture and flavor.

As cheese develops, continual sensory analyses and lab analyses are carried out to examine taste growth, texture, and overall quality. Any deviations from established criteria demand corrective actions to preserve item stability.

Additionally, paperwork and traceability are essential components of effective high quality control, allowing manufacturers to track celebrity from farm to consumer. By carrying out durable QC methods, cheese suppliers can not only enhance product quality however likewise develop consumer depend on, guaranteeing their location in an open market.

Verdict

In verdict, the science of cheese manufacturing encompasses a number of critical points, each substantially impacting the last product. The careful option of milk, the essential duty of bacteria in fermentation, the makeover of liquid milk right into curds with coagulation, and the aging process jointly contribute to the development of one-of-a-kind flavors and appearances. Moreover, stringent high quality control measures make sure that each cheese selection meets well-known requirements, therefore improving customer contentment and preserving the stability of the cheese-making practice.

Luke Perry Then & Now!

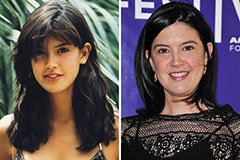

Luke Perry Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!